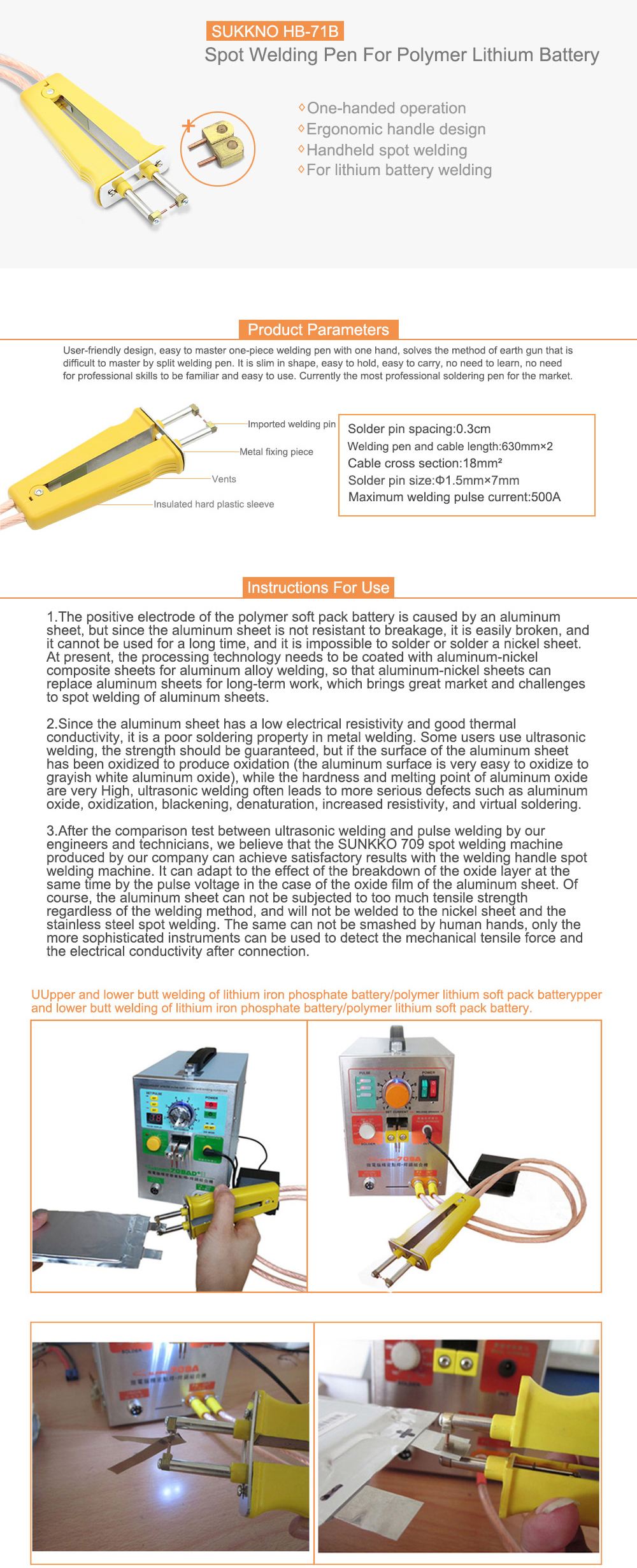

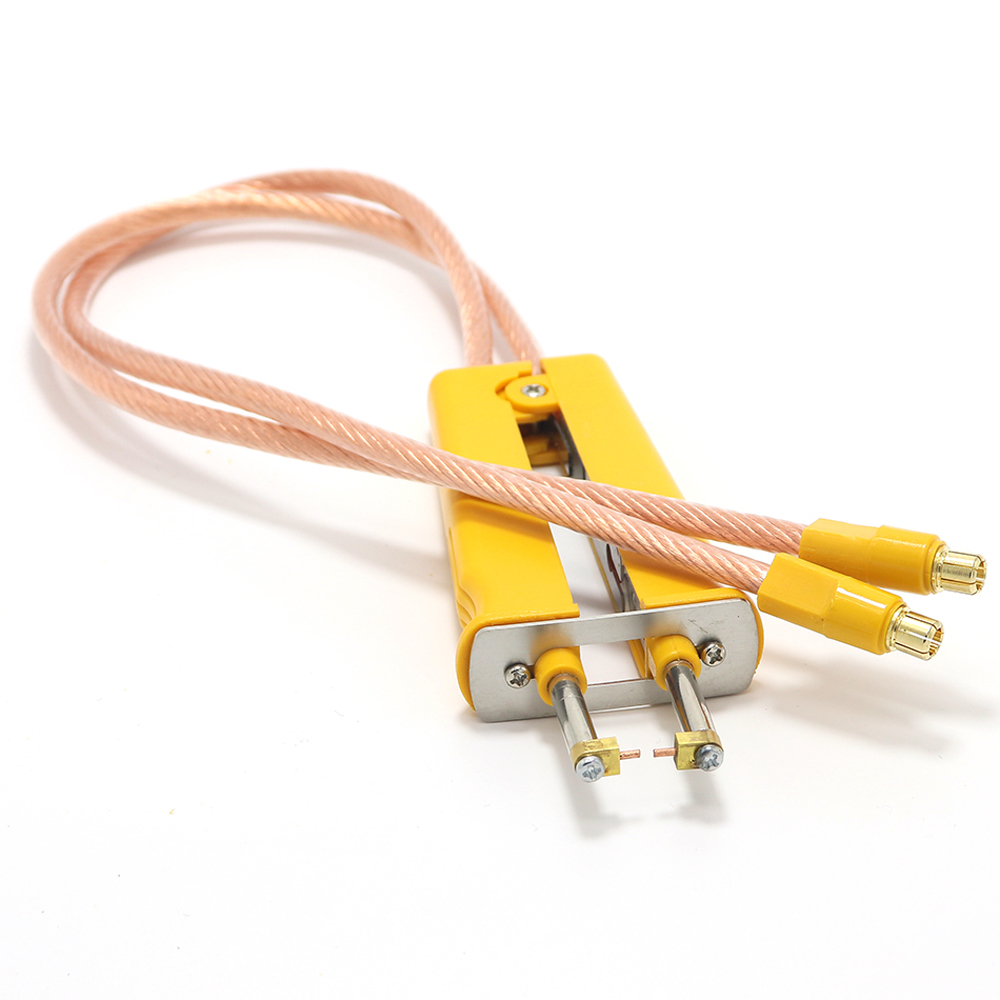

HB-71B Spot Welding Pen Polymer Lithium Battery Spot Welding Machine Pen for 709A 709AD Spot Welding Machine

Description:

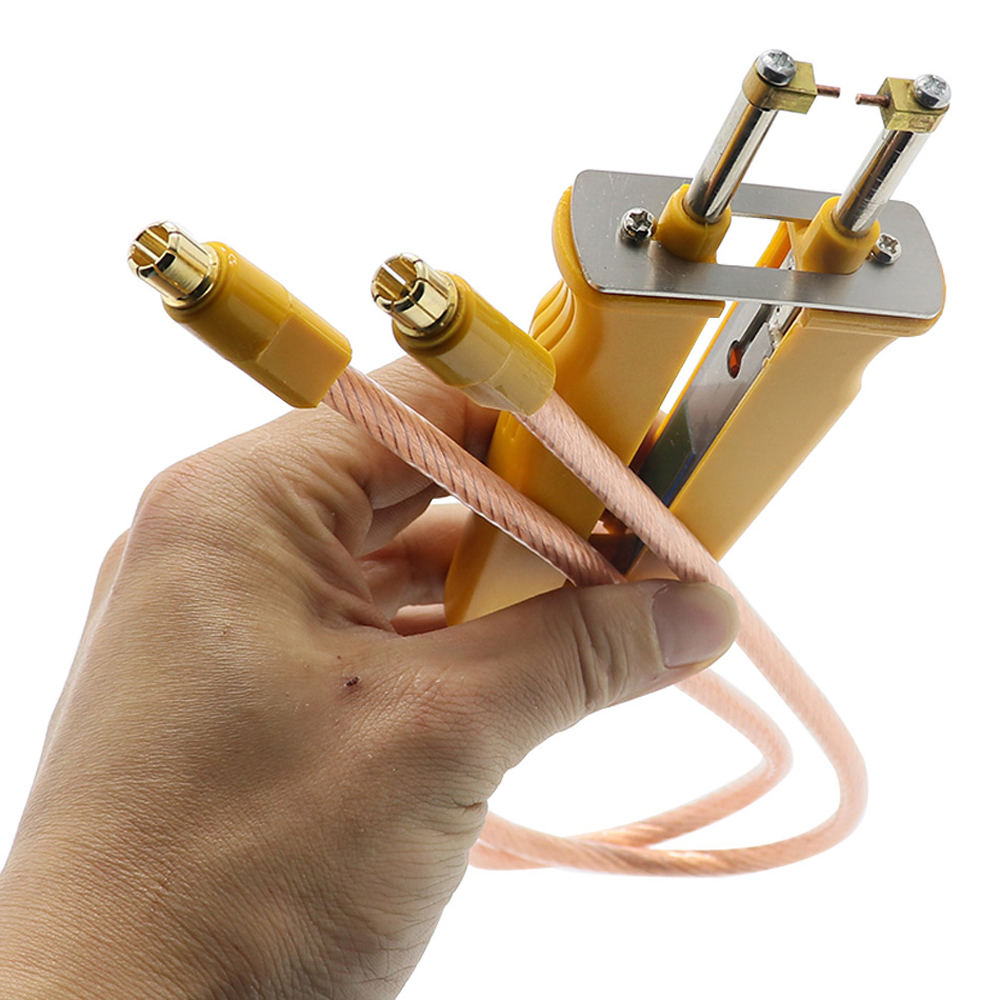

User-friendly design, easy to master one-piece welding pen with one hand, solves the method of earth that is difficult to master by split welding pen. It is slim in shape, easy to hold, easy to carry, no need to learn, no need for professional skills to be familiar and easy to use. Currently the most professional soldering pen for the market.

Specification:

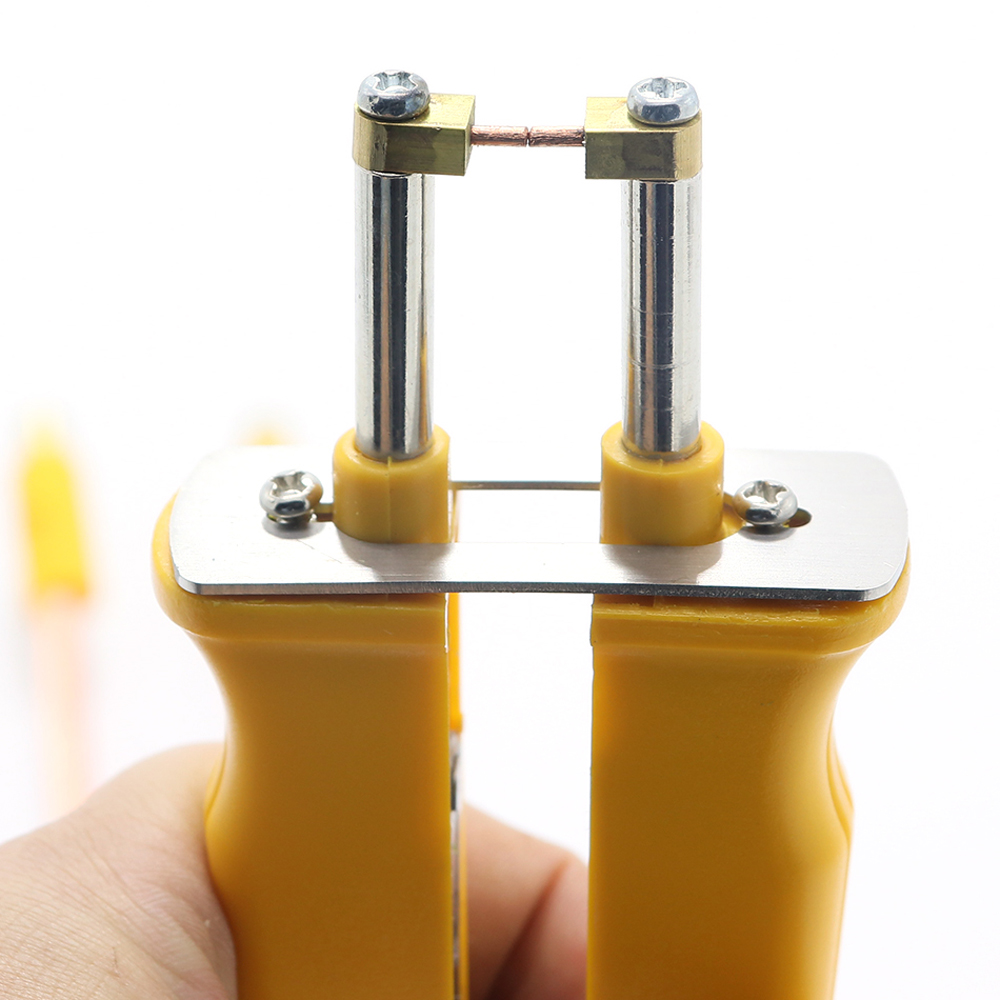

Solder pin spacing: 0.3cm

Welding pen and cable length: 630mm x2

Cable cross section: 18mm⊃2;

Solder pin size: Ф 1.5mm x 7mm

Maximum welding pulse current: 500A

Package Included:Instructions For Use:

1. The positive electrode of the polymer soft pack battery is caused by an aluminum sheet, but since the aluminum sheet is not resistant to breakage, it is easily broken, and it cannot be used for a long time, and it is impossible to solder or solder a nickel sheet. At present, the processing technology needs to be coated with aluminum-nickel composite sheets for aluminum alloy welding, so that aluminum-nickel sheets can replace aluminum sheets for long-term work, which brings great market and challenges to spot welding of aluminum sheets.

2. Since the aluminum sheet has a low electrical resistivity and good thermal conductivity, it is a poor soldering property in metal welding. Some users use ultrasonic welding, the strength should be guaranteed, but if the surface of the aluminum sheet has been oxidized to produce oxidation (the aluminum surface is very easy to oxidize to grayish white aluminum oxide), while the hardness and melting point of aluminum oxide are very High, ultrasonic welding often leads to more serious defects such as aluminum oxide, oxidization, blackening, denaturation, increased resistivity, and virtual soldering.

3. After the comparison test between ultrasonic welding and pulse welding by our engineers and technicians, we believe that the SUNKKO 709 spot welding machine produced by our company can achieve satisfactory results with the welding handle spot welding machine. It can adapt to the effect of the breakdown of the oxide layer at the same time by the pulse voltage in the case of the oxide film of the aluminum sheet. Of course, the aluminum sheet can not be subjected to too much tensile strength regardless of the welding method, and will not be welded to the nickel sheet and the stainless steel spot welding. The same can not be smashed by human hands, only the more sophisticated instruments can be used to detect the mechanical tensile force and the electrical conductivity after connection.

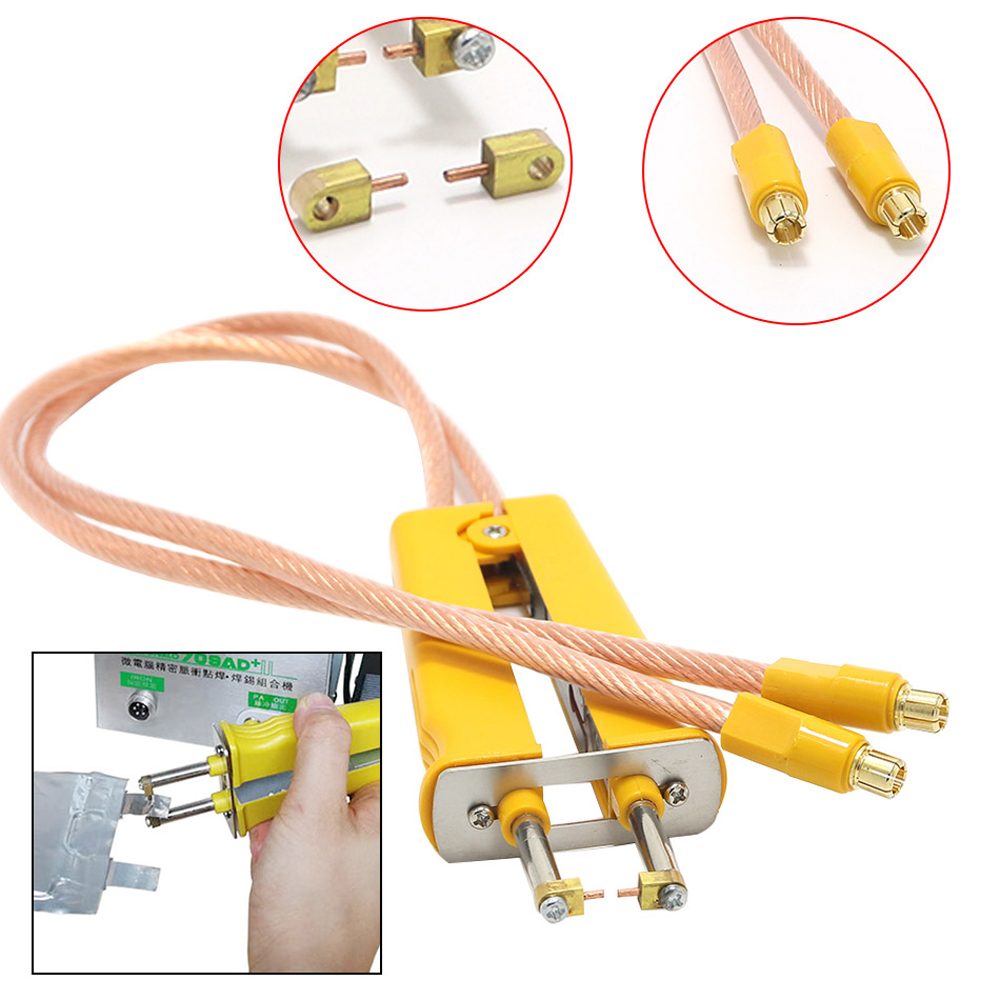

1 x Welding pen

1 x Pairs Small solder pin

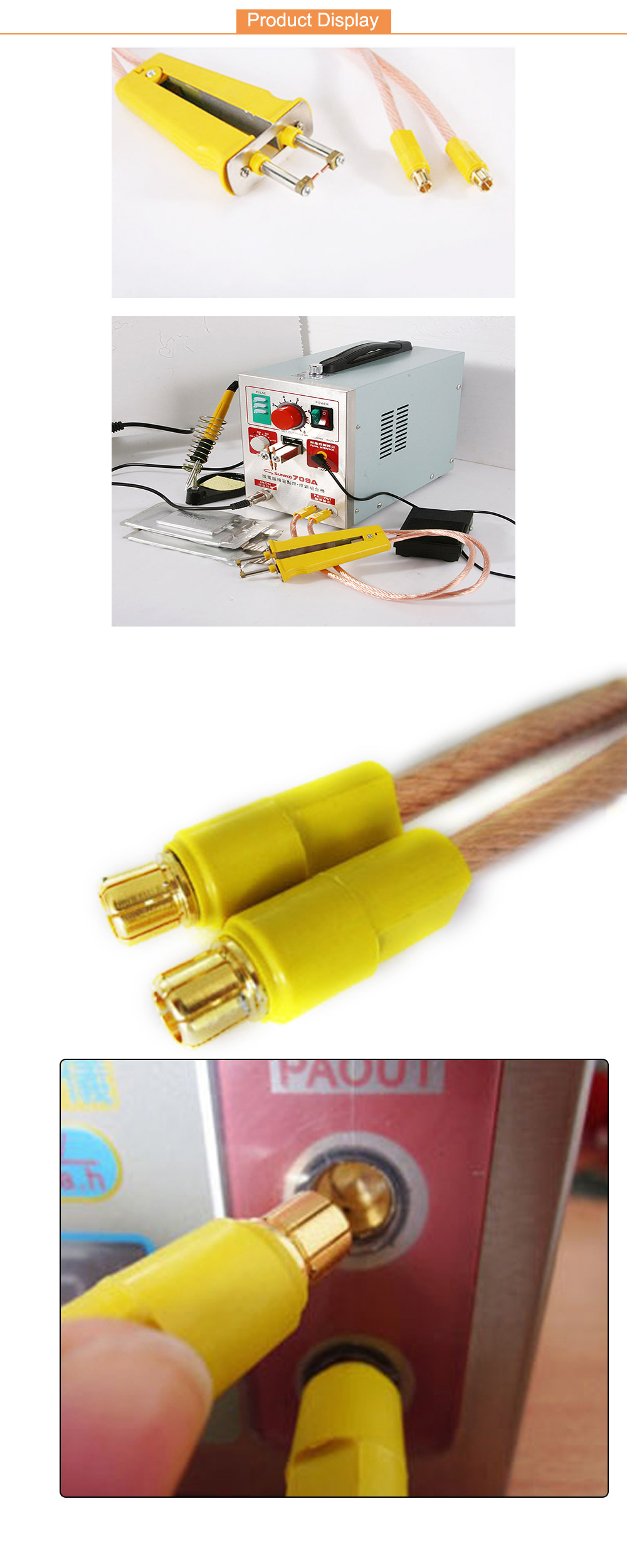

Detail Pictures:

Detail Pictures:

HB-71B Spot Welding Pen Polymer Lithium Battery Spot Welding Machine Pen for 709A 709AD Spot Welding Machine Buy Now